Table of Content

Each pillar has an arm connected to a belt-driven system, moving up and down on the Z-axis. The hotend is connected to the arms and is suspended in the middle of the 3D printer while the print bed is completely unmoving at the base. 3D printing technology has been used in construction for a few years now, but it is only recently that its potential for building houses has begun to be explored.

There are plenty of 3D printer designs out there, and the majority are based around the original work of the RepRap project. 3D printers have the potential to revolutionize the construction industry by making it possible to quickly and easily create complex structures from a variety of materials. There are so many fun designs available from the 3D printing community for a multitude of interesting, useful, and wacky gadgets,as well as incredible toys for kids. 3D printing well-made spare parts, storage containers, organizers,and even mechanical toolsare all possible with home 3D printers.

Step 6: Software

You will need a threaded rod to move the gantry up and down the Z axis. Get a threaded rod that’s taller than what your planning for the height of your printer. You can make your 3D printer as tall as you like, as long as you can find a way for the gantry to move up uninterrupted. Many kits also come with QR codes you can scan to go to a video walkthrough for assembly. They also leave out any guesswork, as they come with instructions to help you assemble the whole printer from start to finish. The first question that we have to deal with is if youshould build a 3D printer.

If this is your first 3D printer, then this is a critical step. Experienced 3D printer builders may choose to forgo watching a walkthrough and just use the instructions instead. Tronxy is another Chinese company that makes 3D printer kits. Creality 3D makes really budget-friendly 3D printers like the Ender 3 Pro and the Ender 5. For bigger sizes and slightly bigger wallets, there’s the Creality CR-10, too. 3D printer kits have come a long way from the Anet A8s of old, so they’re definitely worth checking out.

What are The Steps to Make Your Own 3D Printer?

A 3D printer’s mechanical movement relies on a series of stepper motors. Compared to a regular DC motor, a stepper motor moves in increments or steps, making it more ideal for precise movements. Stepper motors are connected to the three axes, driving the belts and the threaded rods or leadscrews. The extruder also comes with a stepper motor, which is what drives the filament movement in the cold end. In a delta setup, the print bed is not driven by a stepper motor, unlike in a Cartesian 3D printer.

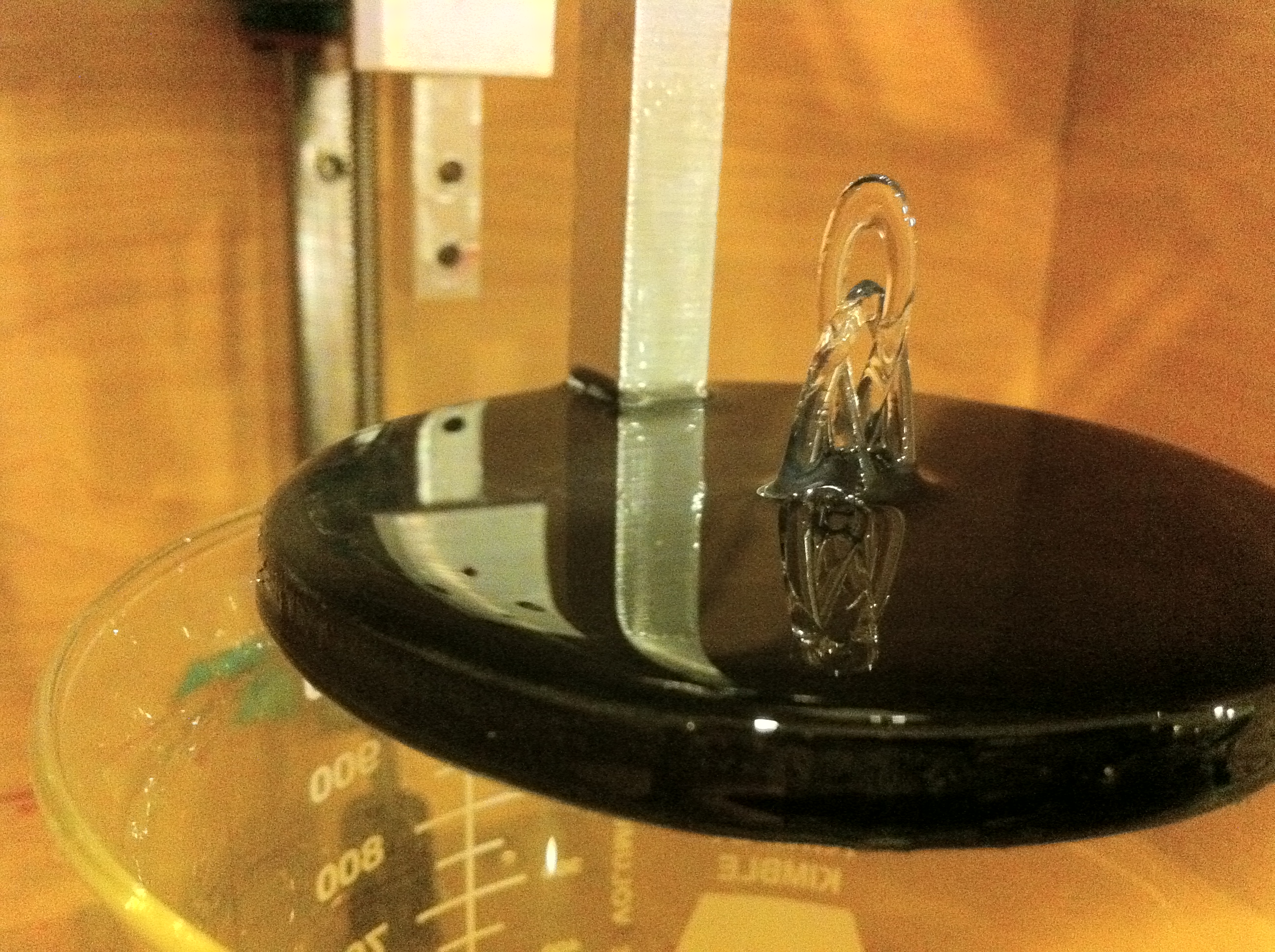

But, as the name suggests, the real beauty of a 3D pen is that it allows you to draw in mid-air, using plastic filament, and create three-dimensional structures that then solidify. Alternatively, you can draw over an existing object to enhance it. Yes, 3D pens really work, if what you want to do is create a 3D model by hand. If you want to create a 3D model based on a pre-existing design, though, you need a 3D printer. Another child-friendly option, the MYNT3D Junior2 3D Pen is designed for ages six years old and above, with an easy-to-grasp design and low temperature nozzle to keep your kids safe.

Starting a Business: A Simple Guide

Even if you only plan to print with PLA, an acrylic-framed 3D printer is still not a good idea due to the material’s fragility. You can use plastic for some components of the 3D printer, but not for the main structure. In a direct drive setup, the cold end and the hotend are directly connected to each other, which means more weight to carry around. This feeder system has a more straightforward structure and is often the recommended setup for flexible filaments.

Add-ons like OctoPrint are easy and have little effect on the overall design/functionality of your printer. Where and how to add the camera maybe something to keep in mind. ABS on top of that needs an enclosure around the printer for optimum quality. Flexible materials like TPU in general work better with direct extrusion as opposed to bowden . It tells the motion components how to move and processes input from the sensors, among other functions.

Another benefit of using a 3D printer to build a house is that it allows for much more complex designs than are possible with traditional methods. The printers work by laying down layers of material until the desired shape is achieved. This means that there are no limiters on what can be created; any design imaginable can be brought to life through 3D printing technology. "Magic" pens are especially useful for children of any age to develop spatial thinking, but adults will also benefit from mastering innovative drawing technology in practice.

This makes a huge difference for those who want to learn deeply about 3D Printing. And, if you wish to do that, never opt for semi-assembled kits. There are different kinds of DIY kits offered by manufacturers.

The standard package of the device includes a 3D printer and a power supply for connecting to the mains. Branded plastic thread for the pen must be purchased separately. The compact 3D pen is a unique creative tool that literally draws in the air.

It prints better than all previous builds, I designed and created. Temperature applies to more than just the temperature at which plastic melts. Different materials have different properties and require proper heating AND cooling. For example, PLA likes to be cooled at the hot-end , whereas ABS can't tolerate moving air and prefers a closed chamber . If you know you want to build a printer the next step (if you haven't set your mind on any yet) is to determine what type of 3D printer you want to build.

Thetoys and gadgetsthat can be made with a 3D printer at home are enough for most of us to yearn for our own 3D printer. 3D printing allows forcustom-made tools and partsthat may be very difficult to find or to order. "The walls are 3D printed. Interior and exterior walls," said Nakata.

No comments:

Post a Comment